Contents

EACV / EAHV e-series Modular Chiller Range (90-1,080kW)

2.10

i-BX Air Cooled Chiller Range, Single Phase (4.3-12.9kW)

2.14

i-BX Air Cooled Chiller Range, Three Phase (10.7-35.1kW)

2.15

i-NX Air Cooled Chiller Range (43.9-129kW)

2.16

i-NX Air Cooled Chiller Range, Low Noise Version (42.6-124kW)

2.17

i-NX-Q SL Air Cooled 4-Pipe Chiller Range, Low Noise Version (45-139kW)

2.18

Traditional Chillers - An Overview

2.19

Chillers for Cooling Only Applications

2.20

Chillers for Heat Pump Applications

2.21

INTEGRA Simultaneous Heating & Cooling 4-Pipe Chiller System

2.22

2.3

Chillers

Contents

2.4

The Innovative Chiller Range

Mitsubishi Electric has manufactured chillers for over 40 years

Climaveneta is a strong European brand, supported by 45 years of customer trust and high

quality production. Its range of energy-saving, low-noise and innovative chiller technology

and in 2015 combined this extensive experience with advanced

further expands the application and customisation capabilities we are now able to offer.

component technology from the commercial air conditioning

Through our technical expertise, long experience and innovative product range, we enable

sector to produce the e-series modular chiller range.

building operators everywhere to significantly improve energy efficiency, reduce running costs

Later the same year, Mitsubishi Electric purchased Climaveneta, enhancing our

and adhere to increasingly tough legislation.

product line up and marking our full scale entry into the chiller market.

We believe that global climate challenges need local solutions.

Our aim is to help individuals and businesses reduce the energy

consumption of their buildings and their running costs.

Our Modular Chiller Range

The benefits of Mitsubishi Electric’s

Chiller systems have been used for decades to deliver controlled

cooling to buildings, but with increasing pressure on energy

e-series modular chiller range:

efficiency and running costs, we now need a low-carbon,

flexible and cost effective option.

High efficiency

The e-series modular chiller range uses highly efficient scroll compressor technology from our

Comprising of Cooling Only and Heat Pump models, Mitsubishi Electric’s e-series

City Multi VRF units, along with advanced inverters and controls to deliver exceptional

modular chiller range allows up to six individual units to be connected together

efficiency and a wide operating range.

to provide a system capacity from 90kW to 1,080kW.

Unique modular approach

Using a modular approach reduces space requirements and simplifies lifting and installation.

A modular approach also lends itself to a staged installation or future HVAC demands, as

modular chillers can be scaled accordingly.

Reduced plant space

Each module can be positioned in a bank of up to six connected units using the same internal

header. Typically 30% ~ 40% space saving can be achieved when compared with traditional

flatbed type chillers.

Internal header pipe:

Coupling supplied

as standard

1st Module

2nd Module

Internal header pipe connecting multiple units

2.5

Chillers

Our Modular Chiller Range

2.6

Our Modular Chiller Range

Low noise levels

By utilising highly efficient components within a uniquely shaped chiller, the e-series modular chiller range offers market leading low noise levels as standard.

Low noise levels are especially important in today’s city centre locations where there is often a mixture of commercial and residential properties in the same area.

Sound pressure levels

Measuring Point

Sound power levels

EACV / EAHV

dB(A)

EACV / EAHV

dB(A)

Model

90kW

150kW

180kW

Frequency (Hz)

63

125

250

500

1000

2000

4000

8000

PWL dB(A)

Front

64

66

68

90kW Module

55.8

60.8

66

67.4

70.1

74

65.2

54.1

77.1

Right

62

68

71

1.5m

150kW Module

59.2

67.4

74.3

79.8

78

75.1

72.3

59.3

84

Back

65

66

67

1.5m

1m

Left

61

70

70

1m

180kW Module

60.8

73.1

76.3

81.5

80.2

77.5

73.8

62.5

86

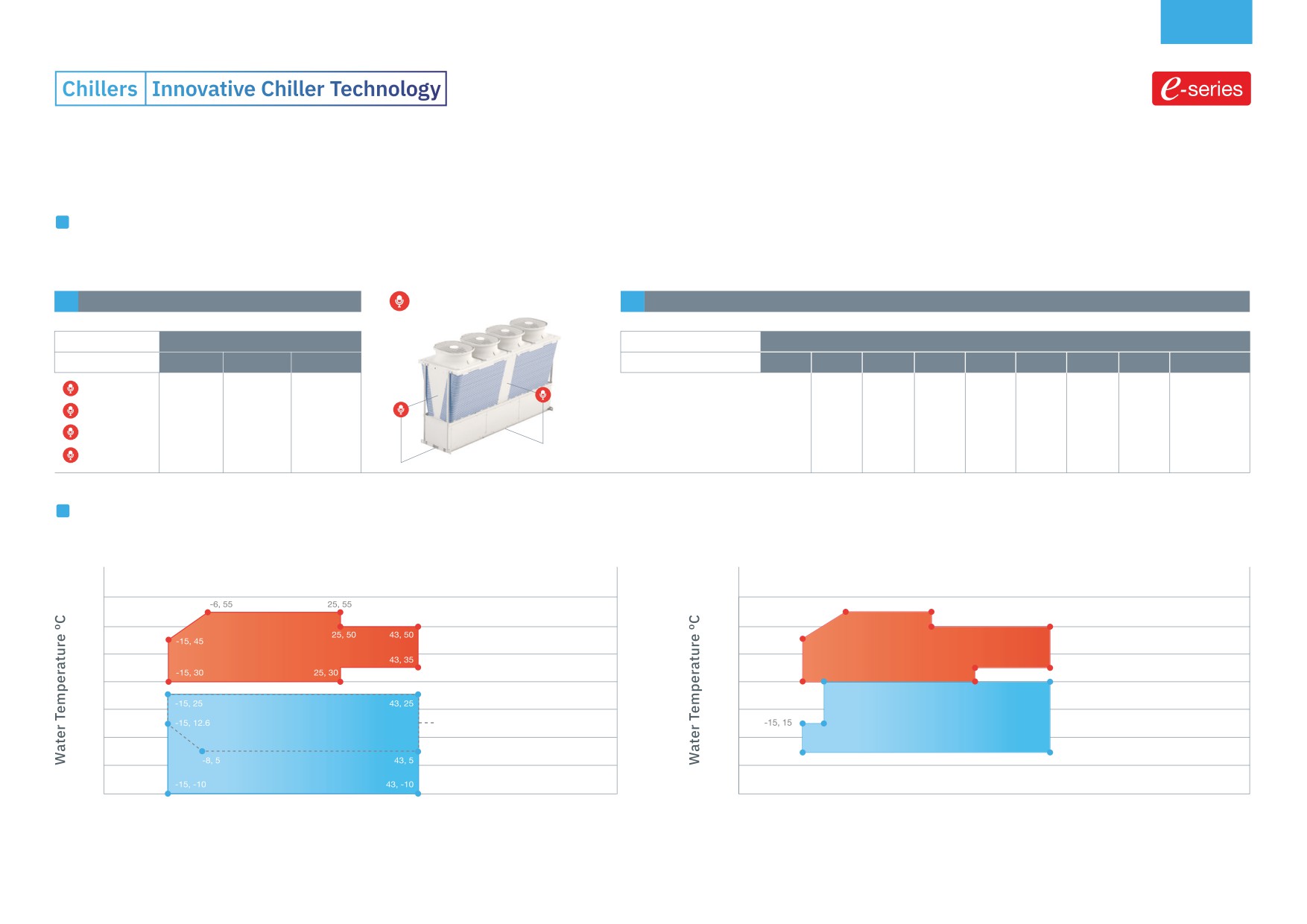

Wide operating range

The e-series modular chiller has a wide operating range in both cooling and heating. The low chilled water temperature range of the 90kW module is ideal for efficient process cooling applications.

90kW Module

150/180kW Modules

60

60

-5, 55

15, 55

50

50

15, 50

43, 50

Hot water range

-15, 45

Hot water range

40

40

25, 35

43, 35

-15, 30

25, 30

30

30

-10, 30

43, 30

20

20

EAHV-P900YAL-N

-10, 15

operational range

10

10

-15, 5

43, 5

Cold water range

Cold water range

0

0

-10

-10

-30

-20

-10

0

10

20

30

40

50

-30

-20

-10

0

10

20

30

40

50

Ambient Temperature ºC

Ambient Temperature ºC

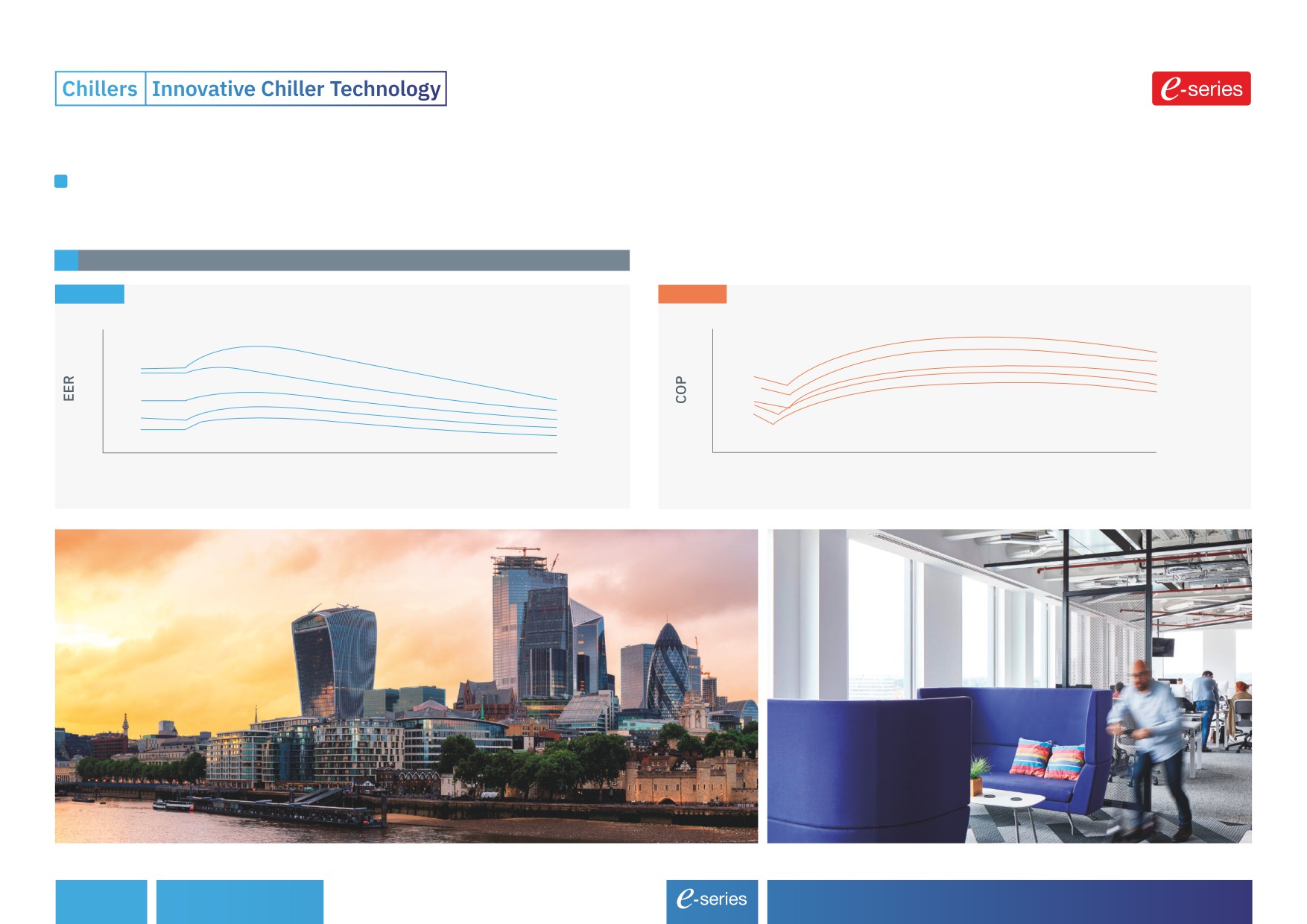

System efficiency and controllability

The e-series modular chiller has multiple inverter driven compressors that allow the unit to operate between 8% ~ 100% of capacity.

By having a broad operating range the chiller has exceptional part load efficiencies, which is where most systems will operate.

High partial load performance

Cooling

Heating

10.0

5.0

Ambient

Temperature

9.0

4.5

15ºC

8.0

4.0

12ºC

7.0

Ambient

3.5

7ºC

Temperature

5ºC

6.0

3.0

15ºC

2ºC

5.0

2.5

20ºC

4.0

25ºC

2.0

30ºC

3.0

35ºC

1.5

2.0

1.0

0

20

40

60

80

100

0

20

40

60

80

100

Capacity (%)

Water outlet 7ºC - Water flow volume 15.5m3

/h

Capacity (%)

Water outlet 45ºC - Water flow volume 15.5m3/h

2.7

Chillers

Our Modular Chiller Range

2.8

Our Modular Chiller Range

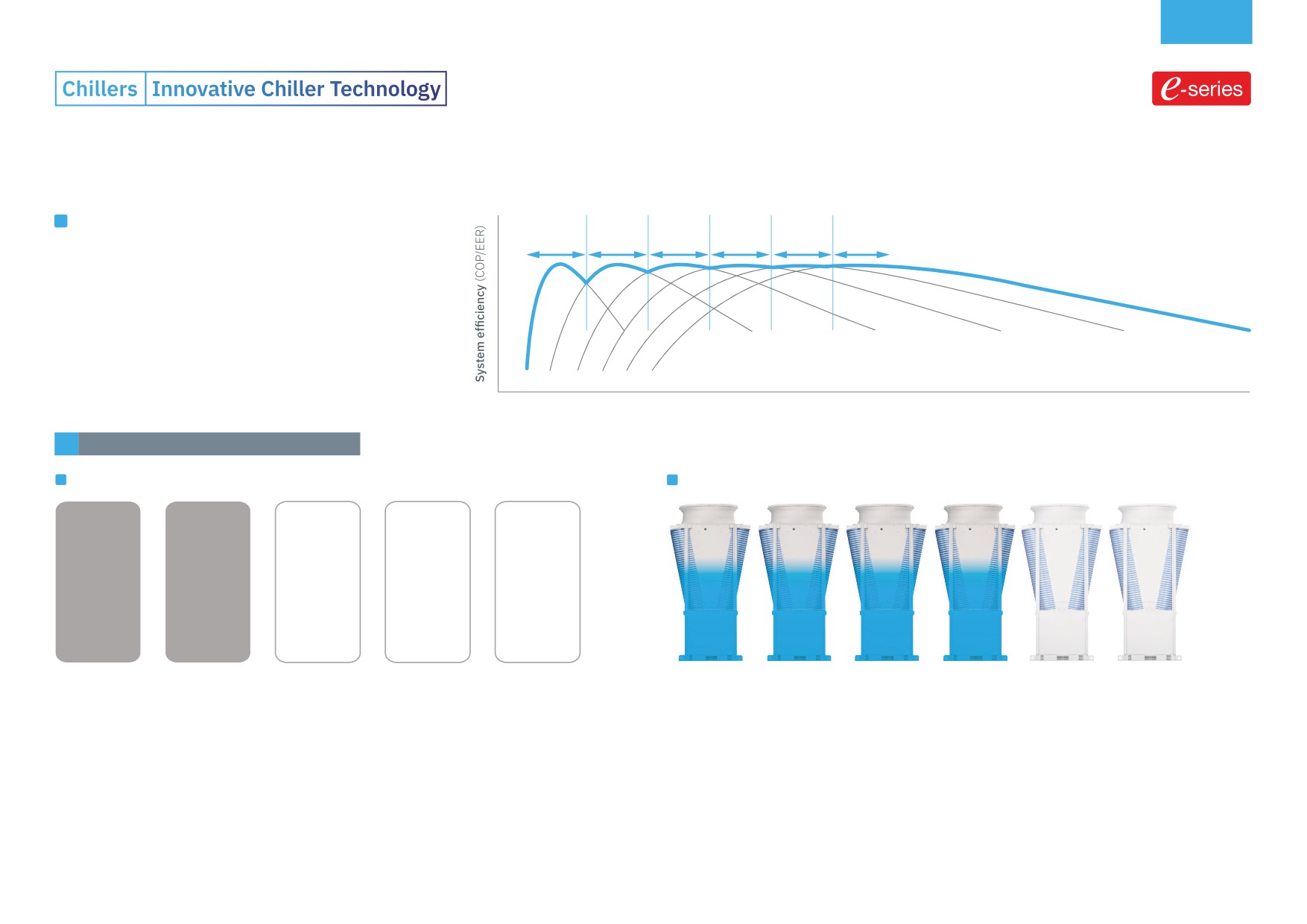

Optimum frequency control

1 unit

2 units

3 units

4 units

5 units

6 units

operation operation operation operation operation operation

When multiple modules are connected, the frequency of

each inverter compressor is controlled during operation

to increase the efficiency of each module, achieving a

high energy saving performance.

This control can be implemented by simply using

our unique M-NET control, without the need for

any other on-site design.

40

50

60

70

80

90

100

0

10

20

30

Capacity comparison [%]

When the overall system load is 40%

Without optimum frequency control

With optimum frequency control

100%

100%

0%

0%

0%

60%

60%

60%

60%

0%

0%

Our modules are equipped with inverter compressors, so the system can be operated in

With non-inverter compressors, it is only possible to turn the unit on or off, and

frequency ranges in which the efficiency of each module is at its peak (between 40 and 60%).

the compressor frequency cannot be adjusted according to the required capacity.

Since the compressors are running at inefficient frequencies, the efficiency of

Optimum frequency control of each unit increases the efficiency of the whole system. In low load

the whole system is lower.

conditions, modules can be switched off to keep remaining modules at optimum efficiency.

The output of the pumps connected to the remaining group can be decreased, and the

efficiency of the whole system is then increased. This control is achieved by connecting to

M-NET. There is no need to prepare sensors, and the instrumentation is simple.

Improved redundancy & resilience

When a non-modular chiller is used as the main 300kW unit, as in this example, the same capacity would also be required as a backup. However, when a Mitsubishi Electric e-series modular chiller

is used, two modules can still operate even if one module goes down, continuing normal operation. This reduces the backup capacity requirement.

Non-modular chiller

Mitsubishi Electric’s e-series modular chiller

Main

For backup

Main

For backup

300kW

300kW

150kW

150kW

150kW

The same capacity is

required for backup

Operation can be continued via one

normal module and one backup module.

Emergency operation mode / Rotation operation

With a single module

Multiple modules

The e-series module contains four compressors (two for the 90kW module)

If one of the e-series modules goes down, the remaining modules can continue to operate.

developed by Mitsubishi Electric. The four compressors operate

Each module can independently control the outlet water temperature. Even if the main module

as two pairs. If something is wrong with one of the

goes down, operation can be continued. When multiple modules are installed, the operating time

two pairs, the other pair can temporarily

of each module in the same system is also equalized according to the load of the whole system.

continue to operate.

Operable

The 90kW module achieves

this by operating its two

compressors independently.

1

2

3

4

5

6

Malfunction

Four compressors

* Units that have been stopped by thermo OFF before the main unit goes down are kept in the thermo OFF mode.

2.9

Chillers

Our Modular Chiller Range