Contents

s-MEXT-G00 DX R32 Close Control System

3.8

s-MEXT-G00 DX R410A Close Control System

3.9

i-NEXT DX R410A Close Control System

3.10

w-NEXT Chilled Water Close Control System

3.11

Accessories / Optional Extras

3.12

3.3

I.T. Cooling

Contents

3.4

Close Control Air Conditioning Systems

Precise Temperature and Humidity Control

Close Control Air Conditioning Systems

Complex I.T. environments are often characterised by variable cooling loads,

The need for high sensible cooling and close

which require a high cooling capacity at full load in order to allow the

control of both temperatures and humidity in

I.T. equipment to operate correctly when it is most needed.

critical I.T. environments has never been higher.

Our I.T. Cooling range makes it possible to keep temperature and humidity constant, even with very wide

Mitsubishi Electric and RC I.T. cooling systems have been

load variations, ensuring the correct room conditions all year round.

designed to fulfil this requirement, reducing operational

The perfect match between efficiency and reliability

costs in the process through the use of highly efficient

technology, with many systems incorporating inverter

With our I.T. cooling systems, both efficiency and reliability are paramount throughout all the stages of

control as standard.

research, design and manufacturing. By using this approach along with over 50 years of manufacturing

experience within the I.T. cooling sector, we are able to offer tailor made I.T. Cooling solutions

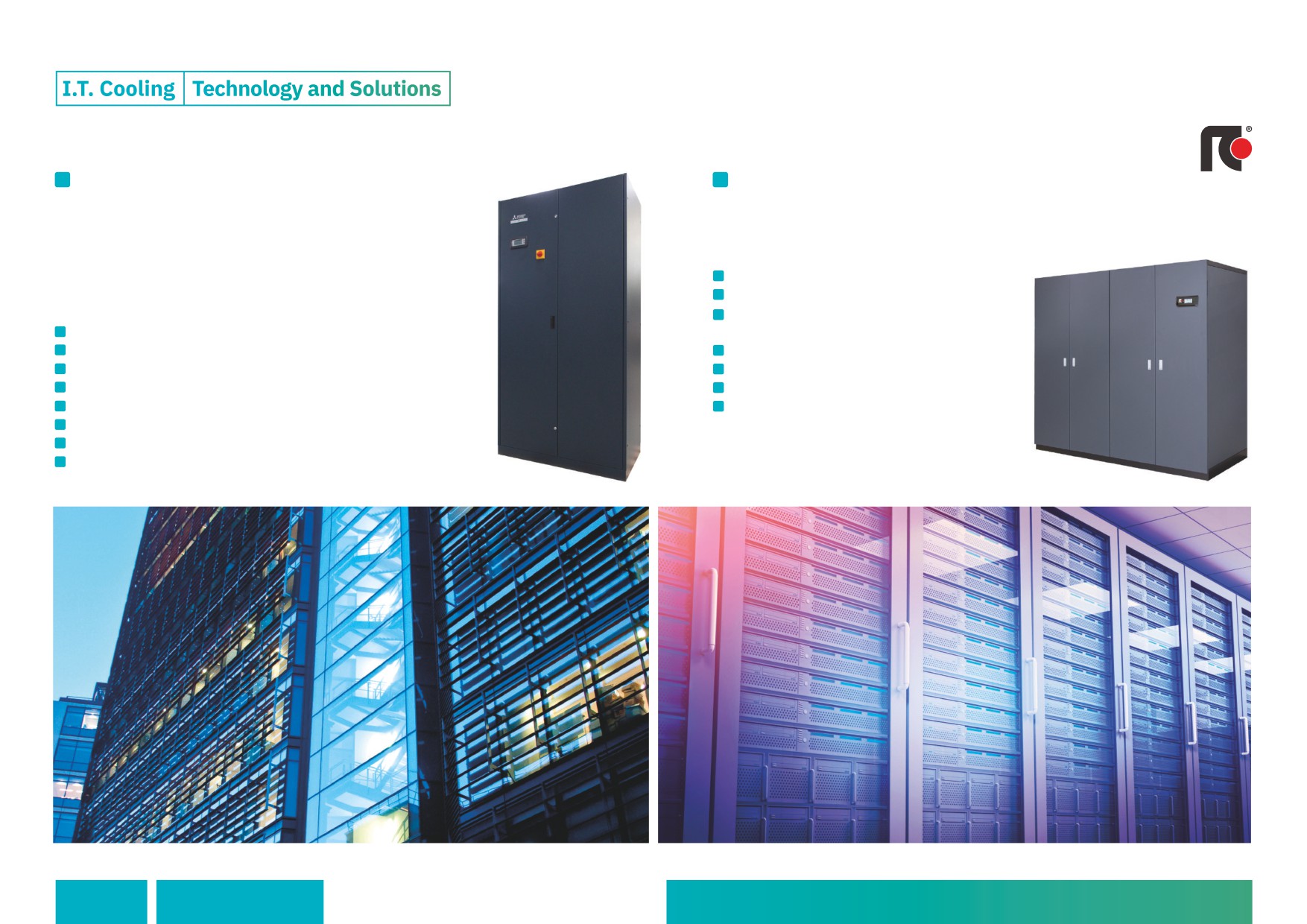

Mitsubishi Electric Perimeter Cooling units

RC Perimeter Cooling Units

The RC I.T. Cooling range of perimeter, upflow or downflow units have been designed

Mitsubishi Electric’s Close Control systems are specifically designed

to cool new and existing I.T. rooms efficiently and effectively. The perimeter range offers

for rooms with a high sensible cooling load that require precise

a broad range of unit types to meet any I.T. perimeter cooling demand.

temperature and humidity control. Because of the need for close

control 24 hours a day, 365 days a year, an inverter driven compressor

DX or chilled water versions available

has been incorporated into the outdoor units, maximising the

Precise temperature and humidity control

energy efficiency of the system.

New generation EC PUL

Connects to Mr Slim Power Inverter outdoor units

(Polymeric ULtralight) high efficiency fans

Easily integrates into existing and new control networks

DC inverter technology

Quick recovery following power failure

Free cooling available

High Sensible cooling

Dual fluid circuits for the highest reliability

Close control of supply temperature

Advanced control systems

Back-up and rotate function available

Easy to install - no space required at the rear of the unit

Inverter driven capacity control

3.5

I.T. Cooling

I.T. Cooling Technology and Solutions

3.6

Multi Density - Launching in 2020

Bringing together leading VRF technology and precision cooling

Mitsubishi Electric’s new Multi Density systems combine the efficiency,

quality and simplicity of City Multi VRF, with high performance in-row

cooling solutions for high density data rooms.

Plug and play

High efficiency

Long pipe runs

Proven technology

In-Row Cooling Solution

Mitsubishi Electric cooling only VRF outdoor units

These systems are suitable for application in modern I.T. infrastructure

Multi Density is ideal for applications where high sensible cooling and close

that is typically characterised by high thermal loads, and are particularly

control of temperature in high density applications is required. Multi Density

suitable for high density racks and blade server cooling in

takes advantage of more than 50 years’ experience of the RC brand within

data centres with hot-spots.

the I.T. Cooling market, coupled with Mitsubishi Electric renowned

quality standards.

The range is able to cope with the high density of the thermal load,

with minimal impact of space in the data centre. In-row technology

This indoor cooling package consists of multiple indoor 'coolside' close coupled

puts the air conditioning unit directly within the rows of racks to

air conditioners, connected to a City Multi VRF outdoor unit. The result is a full

cool the localised heat sources (hot-spots).

inverter multi-split system, designed according to the best quality standards

and dedicated to the most reliable I.T. environments.

Wide operating range

Self-developed inverter compressor technology

M-Net control

Mitsubishi Electric Quality, manufactured in Japan

Air Conditioning for High Density Racks and Blade Servers

Rack Cooling Solutions

Door Unit Cooling Solutions

Rack cooling solutions have been designed for managing high density

Close-coupled cooling is one of the best ways to eliminate hot spots

servers (blade servers), better known as hot-spots.

in a data centre environment.

Through utilisation of advanced technology, these rack cooling units

The major advantage of door cooling systems lie in the fact that they are

deliver targeted cooling exactly where it is required.

installed at the back of the rack (hot aisle), without occupying space that

can then be used for servers. This in turn reduces the number of racks

DX or chilled water versions available

needed per row.

Modulates airflow using EC high efficiency fans. The fans adapt to the

New generation EC high efficiency fans

thermal load detected by the sensors positioned in the hot and cold aisles

Suitable for 42U / 48U racks

Compatible with most rack systems and fully scalable

Minimal intrusion into server space

Dual circuit and free cooling option available for N+1

Dynamic control of air stratification

Can be supplied with rack

3.7

I.T. Cooling

I.T. Cooling Technology and Solutions